Split Bearings – stocked for the Trade

Split bearings are designed to save time, reduce dismantling, and make life easier when access is tight or downtime is expensive. Instead of stripping an entire shaft assembly, you just unbolt, lift the cap, and replace.

They’re ideal for awkward or critical positions in heavy-duty drives, and trusted in industries where uptime isn’t negotiable.

Godiva Bearings now stock the revolutionary design of the brand-new split bearing from GBSplitBearingsUK.

GBSplitbearingsUK are making this normally difficult to source product range available to the worldwide bearing market. Stocked and ready for fast despatch to the Trade only.

What Are Split Bearings?

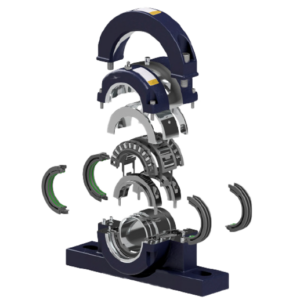

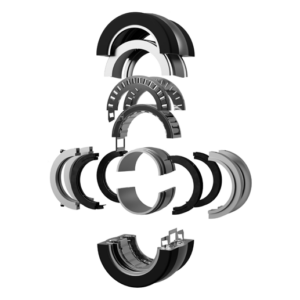

Split bearings are housed bearing assemblies with separable components. The bearing and housing split into top and bottom halves, allowing quick replacement without removing the shaft.

Typical designs include:

- Split roller bearings

- Split spherical bearings

- Split pillow block and plummer block units

They are fully interchangeable with standard shaft sizes and built to carry heavy radial and axial loads.

What Are They Made Of?

Godiva Bearings supplies components manufactured for serious industrial duty:

- Steel bearing inserts – Precision ground and heat-treated

- Cast iron or ductile housings – Durable and vibration-resistant

- Sealing options – Felt, taconite, or labyrinth seals

- Split cages – For ease of assembly and high-speed use

Options available with:

- Grease or oil lubrication setups

- PTFE coatings for reduced friction

- Special clearances on request

Where Are Split Bearings Used?

Split bearings are chosen when downtime is critical or access is limited. Common trade applications include:

- Conveyors: Especially in enclosed or elevated systems

- Pulp and paper mills: Long shafts with minimal access

- Power generation: Turbines, cooling fans, and alternators

- Steel processing: Roller tables and heavy drives

- Marine and offshore: Drives in confined engine rooms

- Mining and quarrying: Crushing and screening equipment

- Cement plants: Kilns, fans, and conveyors

When you can’t shut down for long, split bearings let you swap and go.

What Do Split Bearings Help Prevent?

When fitted correctly, split bearings help prevent:

- Excessive downtime from dismantling machinery

- Damage to shafts during bearing replacement

- Misalignment due to poor reassembly

- Delays in planned or emergency maintenance

- Health and safety risks from invasive stripdowns

They’re all about speed, access, and reliability.

Installation, Use and Maintenance Tips

Trade best practice:

- Always check shaft surface and dimensions before fitting

- Clean all mating surfaces and apply specified torque to bolts

- Use correct seals for the environment – dust, water, or heat

- Align top and bottom halves precisely to avoid stress

- Re-lubricate on schedule using ports provided

Keep a spare insert on hand – that’s the bit that wears.

Conclusion: Save Time, Stay Aligned

Split bearings are built for maintenance in the real world. Quick to fit. Easy to access. Reliable under load.

Godiva Bearings stocks split bearing units, housings, and spares for UK-standard shafts.

Available in a range of sizes – from 30 mm or 1.1/4″ up to 160 mm or 6″ bore, in stock for same-day despatch or collection. Trade-only. Backed by humans who know the job.